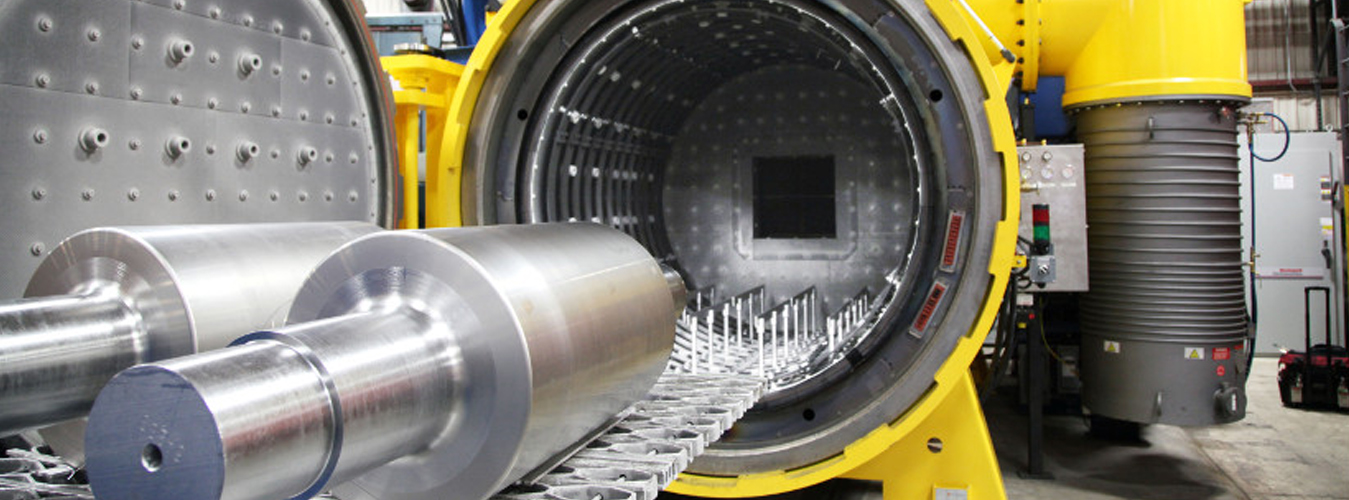

Manufacturing, Refurbishment, Maintenance, Spares, Erection and Commisioning of Vacuum Furnaces

Specification

Processes:

- Vacuum Hardening

- Vacuum Tempering

- Vacuum Brazing

- Vacuum Annealing

Sizes of Hot-zone & Capacity.

- 350 X 350 X 450 mm - 100 kgs

- 400 X 400 X 600 mm – 300 Kgs

- 600 X 600 X 600 mm – 500 kgs

- 900 X 900 x 1200 mm – 800 Kgs

- Any possible sizes available on request

Vacuum

- Fine vacuum – (10(-2) mbar)

- High vacuum – (10(-5) mbar)

- Partial Pressure – ( 1-15 mbar)

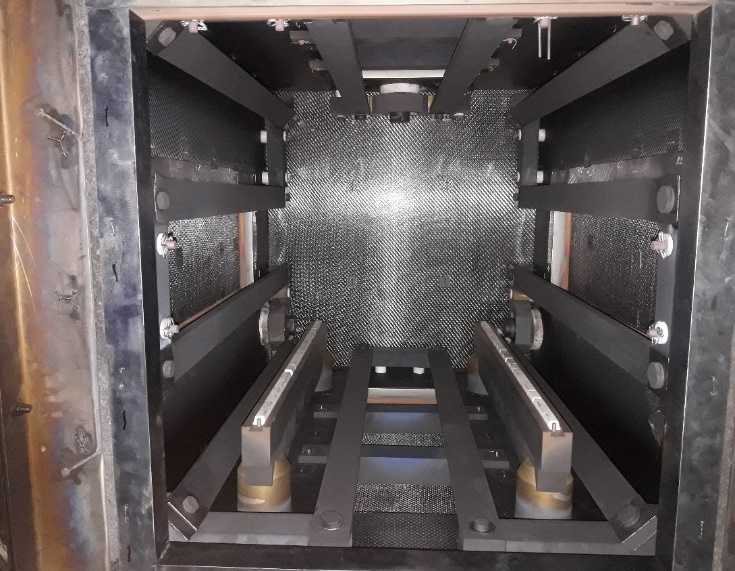

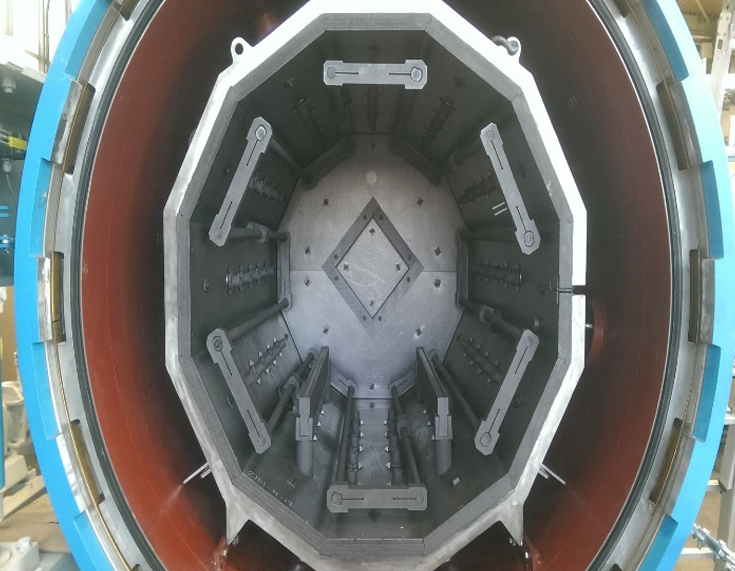

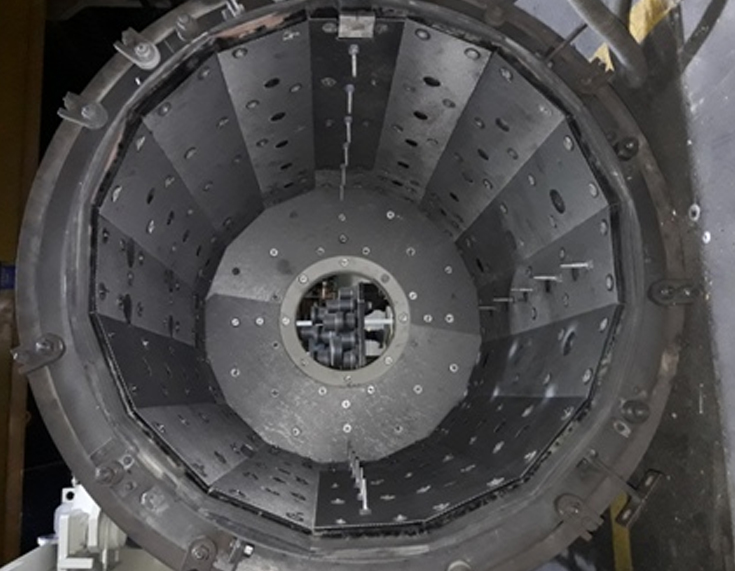

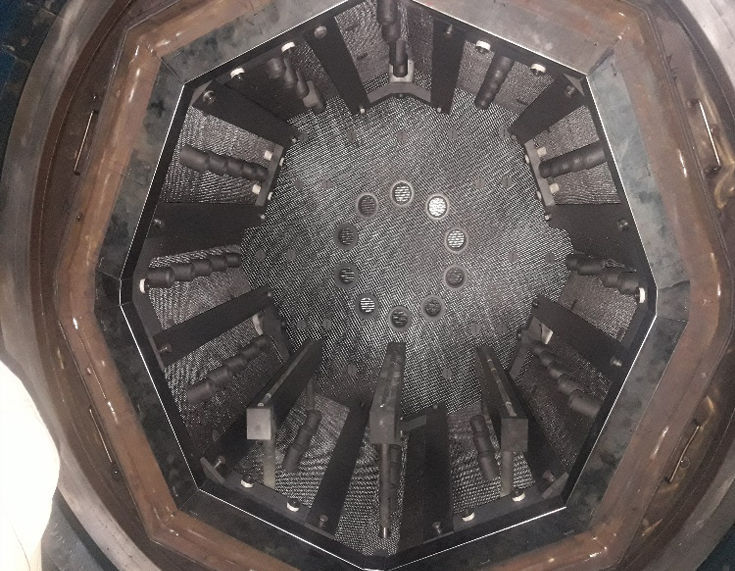

Hot-Zone

- Size – Cubic or Cylindrical, As per part composition and type of heat treatment.

- Heating Zone – One

Controllable zone heating option available.

Convective Heating

- For uniform, homogenous and Rapid Heating upto 750 degC.

Quench Parameter

- Quench Pressure - Programmable quench pressure between 1.5 -10 Bar.

- Quench Gases – Nitrogen. Argon or Helium

Quenching Direction

- Vertical – Top to Bottom

- Horizontal – Left to Right

- Vertical/ Horizontal – Four Direction Quenching

- 360 Degree – Nozzle quenching.

Accessories for Vacuum heat Treatment Plant

- Loading stacker (Manual / Battery operated)

- Loading / charge Fixture.

- Gas storage Tank (Buffer tank)

- Gas manifold ( for Buffer Tank Loading)

- Cooling water system

- Tempering Furnaces

Services

- Hot -zone Relining – (Graphite / Molybdenum)

- Refurbishment of old vacuum furnace

- AMC Services

- Breakdown Maintenance

- Helium Leak detection and vacuum leak identification & Rectification.

- PLC and Scada upgradation.

- Shifting, Erection, Commissioning support

Spares

- Copper Tube Heat Exchangers

- Graphite / CFC fixtures

- Door Seals and O-rings

- Ceramic parts

- Graphite parts

- Molybdenum parts

- Electric feed troughs

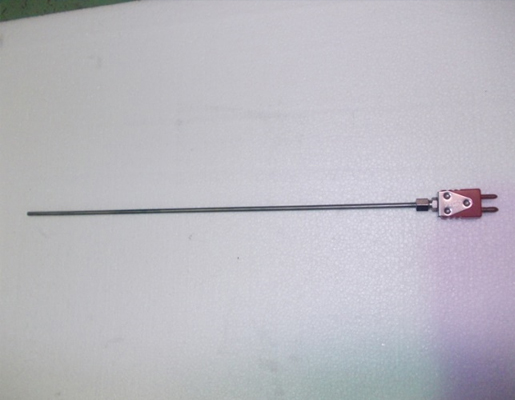

- Pressure switches, Thermocouples, Vacuum gauges etc.

- Pneumatic cylinders, Actuators etc.

GRAPHITE SPARES

CERAMIC SPARES

MOLYBDENUM PARTS

THERMOCOUPLE

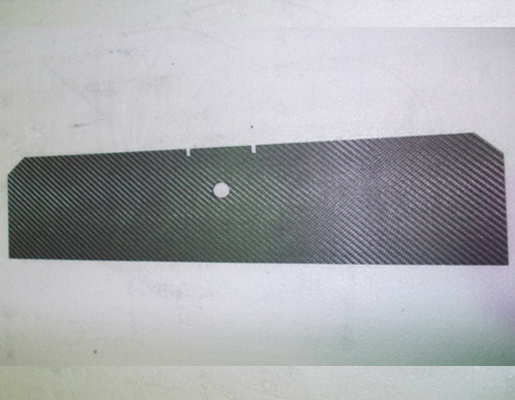

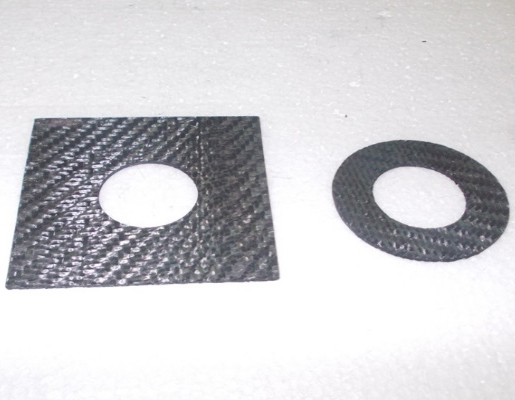

CFC PARTS